Forklift Safety Tips for Operating in a Busy Warehouse

Sean Cambern • June 29, 2025

Operating forklifts in a bustling warehouse environment requires skill, awareness, and adherence to strict safety protocols. With heavy loads, tight spaces, and constant activity, ensuring safety is critical to prevent accidents, injuries, and costly downtime. At AAA Forklift, we prioritize safety in all our forklift sales, rentals, and repair services. Here are essential safety tips to keep your warehouse operations running smoothly and safely.

1. Get Proper Training and Certification

Forklift operation is not a "learn-as-you-go" task. All operators must complete certified training programs that cover equipment handling, load management, and workplace hazards. OSHA requires operators to be trained and certified before operating forklifts. Ensure your team is up to date on certifications, and consider refresher courses to reinforce safe practices.

2. Conduct Pre-Shift Inspections

Before starting a shift, inspect your forklift thoroughly. Check for issues like worn tires, hydraulic leaks, malfunctioning brakes, or damaged forks. A quick pre-use checklist can prevent accidents caused by equipment failure.

Key Checks:

- Tire condition and pressure

- Fork and mast integrity

- Brakes, horn, and lights

- Fluid levels (for gas or diesel models)

If you spot issues, contact our expert repair team to get your forklift back in top shape.

3. Know Your Load Limits

Overloading a forklift is a leading cause of tip-overs, which can be catastrophic in a busy warehouse. Always check the forklift’s load capacity plate and ensure loads are stable and secure. Distribute weight evenly and avoid lifting loads that exceed the machine’s capacity.

4. Maintain Clear Visibility

In a busy warehouse, visibility is critical. Always ensure you have a clear line of sight when moving loads. If a load obstructs your view, travel in reverse or use a spotter to guide you. Keep mirrors clean and use backup alarms or warning lights, especially in high-traffic areas.

5. Follow Safe Driving Practices

Treat forklifts like the powerful machines they are. In a busy warehouse, reckless driving can lead to collisions or injuries. Stick to these rules:

- Obey warehouse speed limits and slow down at intersections or corners.

- Keep a safe distance from other vehicles, pedestrians, and obstacles.

- Avoid sudden stops or sharp turns that could destabilize loads.

6. Watch for Pedestrians

Warehouses are often shared spaces with workers on foot. Always yield to pedestrians and use horns or warning signals when approaching busy areas. Establish clear pedestrian pathways and use barriers or signage to separate foot traffic from forklift zones.

7. Avoid Hazardous Surfaces

Uneven floors, wet surfaces, or debris can cause forklifts to lose traction or tip over. Inspect warehouse floors regularly and clean up spills immediately. Avoid driving over loose objects like pallets or straps, and ensure ramps or inclines are within the forklift’s safe operating range.

8. Use Personal Protective Equipment (PPE)

Operators and nearby workers should wear appropriate PPE, such as hard hats, high-visibility vests, and steel-toe boots. In noisy warehouses, ear protection may also be necessary. Ensure your team is equipped to handle the demands of a busy environment.

9. Park and Store Forklifts Safely

When not in use, park forklifts in designated areas away from high-traffic zones. Lower forks to the ground, turn off the power, and engage the parking brake. Remove keys to prevent unauthorized use. Proper storage reduces the risk of accidents during off-hours.

10. Stay Alert and Avoid Distractions

Busy warehouses are full of distractions, but operators must stay focused. Avoid using phones or other devices while operating a forklift. Be aware of your surroundings, including other equipment, workers, and changing warehouse conditions.

Why Safety Matters

Forklift accidents can lead to serious injuries, damaged goods, and costly disruptions. By following these safety tips, you create a safer workplace and boost productivity. At [Your Company Name], we’re committed to supporting your safety goals with high-quality forklifts, reliable repairs, and flexible rental options tailored to your warehouse needs.

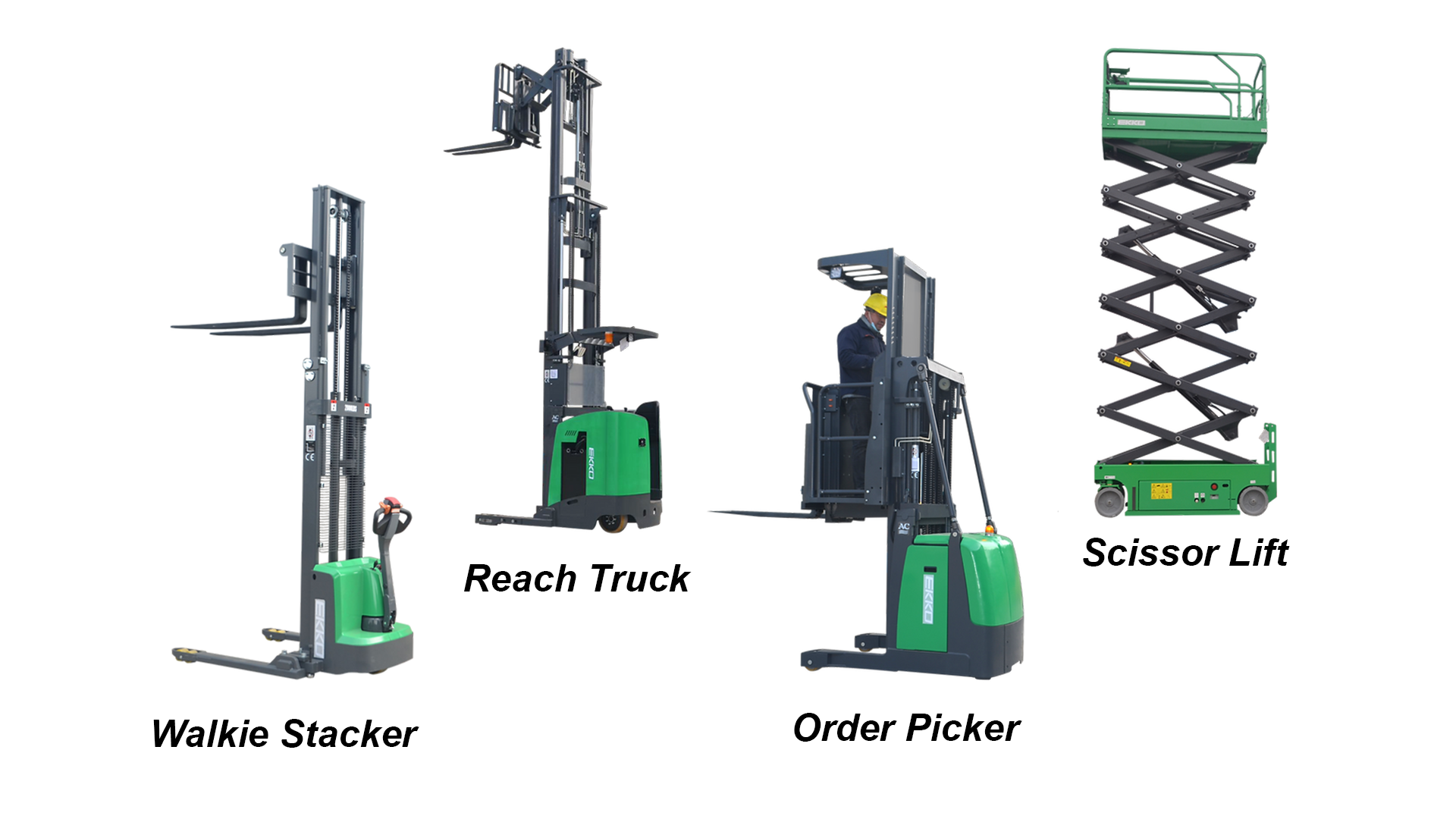

For more information on our forklifts, pallet jacks, stackers, reach trucks, order pickers, or scissor lifts, or to schedule preventative maintenance service or a repair, call Sean Cambern at (510) 470-9771

today. Let’s keep your warehouse moving safely and efficiently!

Material Handling is in our name, and it includes a variety of equipment, including these described below. Electric Pallet Jack: The Workhorse for Horizontal Moves The electric pallet jack, also known as a powered pallet truck or electric pallet truck, is a motorized device designed to lift and transport pallets with ease. Unlike manual versions that require physical pumping, this equipment uses battery power to handle the heavy lifting, making it a staple in modern logistics. Key features include compact designs for tight spaces, durable construction, and options like integrated weight scales that calculate loads during lifting. Capacities typically range from 3,300 to 8,000 lbs, with some models featuring lead-acid or lithium batteries for extended runtime. Advanced versions may include rider platforms for longer distances, enhancing productivity in demanding environments. Primarily used for horizontal movement, electric pallet jacks excel in unloading delivery trucks, maneuvering small loads over short distances, and navigating narrow aisles in warehouses. They're perfect for retail stockrooms, manufacturing floors, and distribution centers where quick, effortless pallet relocation is needed, reducing strain on workers and speeding up workflows. Electric Stacker: Elevating Pallets with Precision An electric stacker, often called a walkie stacker, is a pedestrian-operated machine that combines the mobility of a pallet jack with vertical lifting capabilities. The operator walks behind or alongside, steering via a handle, while electric motors power both drive and lift functions. Notable features include high-torque 24V DC motors for smooth operation, lift heights up to 130 inches (or about 4.8 meters), and load capacities from 3,300 to 4,000 lbs. Many models boast ergonomic controls, automatic braking systems, stability enhancements, and user-friendly interfaces like programmable auto-off to conserve battery life. Safety features such as speed regulation and emergency stops are standard, making them reliable for intensive use. Electric stackers are ideal for stacking pallets in stores, factories, and warehouses, especially in narrow aisles or confined spaces. They transport loads efficiently, handle racking operations, and support inventory management by lifting goods to higher shelves, all with minimal effort compared to manual stackers. Reach Truck: Mastering Narrow Aisles and High Racks The electric reach truck is a specialized forklift designed for indoor warehouse efficiency, featuring forks that extend forward (via a pantograph mechanism) to access racking without moving the entire vehicle. This allows for operation in tight spaces, with the operator typically seated sideways for better visibility. Standout features include AC drive and lift systems, multifunction control handles, and the ability to reach heights up to 30 feet. They often have stabilizing legs, telescoping booms for variable reach, and batteries that support high-capacity loads (up to several thousand pounds). Energy-saving designs and superior maneuverability make them stand out in dense storage setups. Reach trucks are primarily used for pallet storage and retrieval in narrow-aisle warehouses, where space optimization is key. They excel at lifting goods to high racks, distributing loads evenly, and performing quick, precise maneuvers in environments like distribution centers or cold storage facilities. Their design minimizes aisle width requirements, maximizing storage density. Order Picker: Picking Orders from the Heights An electric order picker is a type of walkie stacker that elevates the operator along with a platform to access high shelves, enabling the direct selection of individual items rather than entire pallets. It's essentially a personnel lift integrated with material handling. Features include open operator compartments for visibility, reach heights up to 32 feet, and versatile platforms that handle various item sizes without forks for full pallets. Battery-powered with flexible controls, these machines are compact, quiet, and equipped with safety features like harness attachments and stability systems. Common uses revolve around order fulfillment in e-commerce warehouses, retail distribution, and inventory-heavy operations. They allow workers to pick and transport items from elevated racking, such as auto parts or furniture, streamlining processes in customer-order facilities and reducing the need to lower entire loads. Electric Scissor Lift: Vertical Access for Safe Elevated Work The electric scissor lift is a battery-powered aerial work platform that uses a crisscross (scissor-like) mechanism to raise and lower a stable enclosure vertically. Unlike forklifts, it's focused on elevating people and tools rather than heavy pallets. Key features encompass proportional controls for smooth operation, safety interlocks, smart diagnostics, and low engine noise for indoor suitability. Platforms can extend for added reach, with capacities supporting multiple workers and equipment, often up to several hundred pounds and heights of 20-40 feet depending on the model. Electric scissor lifts are versatile for maintenance, installation, and inspection tasks in warehouses, construction sites, and facilities management. They provide temporary access to elevated areas for painting, electrical work, or stocking high shelves, excelling in narrow or indoor spaces where stability and ease of use are crucial.

Forklifts are the backbone of warehouse operations, and their efficiency depends heavily on their power source. Traditionally, lead-acid batteries have powered forklifts, but lithium-ion batteries are quickly becoming the preferred choice. Here’s a breakdown of why lithium-ion batteries hold a clear advantage over lead-acid batteries for forklifts. 1. Superior Energy Efficiency Lithium-ion batteries offer higher energy density, meaning they store more energy in a smaller, lighter package. This allows forklifts to operate longer on a single charge compared to lead-acid batteries, which are heavier and require more frequent recharging. For example, a lithium-ion battery can provide consistent power output throughout its discharge cycle, while lead-acid batteries lose voltage as they deplete, reducing forklift performance over time. 2. Faster Charging and Opportunity Charging One of the biggest advantages of lithium-ion batteries is their fast charging capability. Unlike lead-acid batteries, which require 6-8 hours to charge fully and a cooling period afterward, lithium-ion batteries can reach full charge in 1-2 hours. They also support opportunity charging, allowing operators to charge during breaks without damaging the battery. This eliminates the need for battery swaps and keeps forklifts operational throughout multi-shift environments. 3. Longer Lifespan Lithium-ion batteries last significantly longer than lead-acid batteries. While a lead-acid battery typically endures 1,000-1,500 charge cycles, a lithium-ion battery can last 2,000-3,000 cycles or more. This extended lifespan reduces replacement costs and downtime, making lithium-ion a cost-effective choice over time despite their higher upfront cost. 4. Reduced Maintenance Lead-acid batteries require regular maintenance, including watering, equalizing charges, and cleaning to prevent corrosion. Lithium-ion batteries, on the other hand, are virtually maintenance-free. They don’t require watering or special charging procedures, saving time and labor costs while reducing the risk of operator errors. 5. Environmental Benefits Lithium-ion batteries are more environmentally friendly than lead-acid batteries. Lead-acid batteries contain toxic materials like lead and sulfuric acid, which pose disposal challenges and environmental risks. Lithium-ion batteries, while not perfect, have a lower environmental impact and are easier to recycle. Additionally, their energy efficiency reduces overall power consumption, contributing to greener operations. 6. Enhanced Safety Safety is critical in warehouse settings. Lithium-ion batteries have built-in Battery Management Systems (BMS) that monitor temperature, voltage, and current to prevent overcharging or overheating. Lead-acid batteries, by contrast, can release hazardous gases during charging, requiring well-ventilated areas and careful handling to avoid accidents. 7. Space and Weight Savings Lithium-ion batteries are lighter and more compact than lead-acid batteries, which can improve forklift maneuverability and reduce wear on components like tires and brakes. The reduced weight also allows for better load capacity and efficiency, particularly in narrow-aisle or high-lift applications. Cost Considerations While lithium-ion batteries have a higher initial cost, their long-term savings are substantial. Reduced maintenance, fewer replacements, and increased uptime translate to a lower total cost of ownership. For businesses running multi-shift operations or high-throughput warehouses, the return on investment becomes evident quickly. Conclusion Switching to lithium-ion batteries for forklifts offers undeniable advantages over traditional lead-acid batteries. From faster charging and longer lifespan to reduced maintenance and environmental benefits, lithium-ion technology is transforming warehouse efficiency. For businesses looking to optimize operations and cut costs in the long run, lithium-ion batteries are a smart investment.

Forklifts are essential equipment in many warehouses and industrial settings. Understanding common forklift terminology is important for anyone working with or around forklifts. Here are some common terms used when discussing forklifts: 1. Mast: The vertical assembly on the front of the forklift that raises and lowers the load. 2. Forks: The two metal arms at the front of the forklift that slide under the pallet to lift and carry loads. 3. Tines: Another term for the forks. 4. Load backrest: A vertical bar or plate located behind the forks that prevents the load from shifting backward. 5. Capacity plate: A metal plate located on the forklift that indicates the maximum weight the forklift can safely lift. 6. Counterweight: Heavy iron weight located at the rear of the forklift to counterbalance the weight of the load being lifted. 7. Overhead guard: A metal roof-like structure that provides protection to the operator from falling objects. 8. Tilt cylinders: Hydraulic cylinders that allow the operator to tilt the mast and the forks forward or backward. 9. Side shift: A feature that allows the operator to move the forks left or right hydraulically. 10. Forklift attachment: Additional equipment such as clamps, rotators, or sideshifters that can be fitted to the forklift for handling specific types of loads. Understanding these terms can improve communication and safety in the workplace when operating forklifts. Whether you're a forklift operator or working alongside forklifts, knowing these terms is essential for maintaining a safe and efficient working environment.

Understanding the factors that affect a forklift's lift capacity is crucial for ensuring safe and efficient operation in a warehouse or construction site. Several key factors influence a forklift's ability to lift and carry loads, and being aware of these factors can help operators make informed decisions and prevent accidents. 1. Load Center: The load center is the distance from the face of the forks to the center of gravity of the load. Forklifts are rated for a specific load capacity at a specific load center. If the load is not centered properly, it can affect the forklift's stability and lifting capacity. 2. Mast Tilt Angle: The mast tilt angle can impact the forklift's capacity to lift loads. Tilting the mast forward or backward can change the weight distribution and affect the stability of the forklift. 3. Lift Height: The maximum lift height of a forklift can also impact its load capacity. As the lift height increases, the forklift's capacity may decrease, so it's important to consider both the weight and height of the load. 4. Fork Length: Longer forks can reduce a forklift's load capacity, as they can cause the load center to shift and affect stability. It's crucial to use the correct fork length for the specific loads being handled. 5. Tire Type and Condition: The type and condition of the forklift's tires can significantly impact its stability and capacity. Worn or damaged tires can reduce traction and affect the forklift's ability to lift loads safely. 6. Forklift Model and Specifications: Different forklift models have varying load capacities based on their design and specifications. It's essential to refer to the forklift's manual and specifications to determine its exact lifting capacity under different conditions. By considering these factors and ensuring that forklift operators are well-trained in load handling and safety protocols, businesses can maintain a safe and productive work environment while maximizing the forklift's lifting capacity.

Switching from propane to lithium-ion battery-powered forklifts can offer several key benefits for businesses. First and foremost, lithium-ion batteries are more environmentally friendly than propane, producing zero emissions during operation. This can help companies reduce their carbon footprint and contribute to a cleaner, healthier work environment. Additionally, lithium-ion battery-powered forklifts are known for their efficiency and lower operating costs. They often require less maintenance than propane forklifts, resulting in decreased downtime and overall lower long-term operating expenses. Moreover, lithium-ion batteries offer the advantage of fast and opportunity charging, allowing for more flexibility in operations and potentially eliminating the need for dedicated battery changing areas. This streamlined approach can enhance productivity and workflow in busy warehouse and distribution settings. Furthermore, lithium-ion battery-powered forklifts tend to have longer lifespans than propane counterparts, providing a reliable and long-term solution for material handling needs. Overall, making the switch to lithium-ion battery-powered forklifts can lead to cost savings, improved efficiency, and a reduced environmental impact, making it a compelling choice for modern businesses.

Forklifts are essential equipment for warehouses, factories, and other industrial facilities. Whether you need to move heavy loads, stack pallets, or transport goods, a forklift can make your work much easier. However, forklifts can also be expensive, especially if you're buying a new one. That's why many businesses choose to buy used forklifts instead. If you're considering buying a used forklift, here are some tips to help you make the right decision. 1. Determine your needs Before you start shopping for a used forklift, you need to determine your specific needs. What type of work will the forklift be used for? What's the maximum weight it needs to lift? What's the maximum height it needs to reach? By answering these questions, you can narrow down your search and find a forklift that meets your requirements. 2. Check the forklift's condition When you're inspecting a used forklift, you need to look for signs of wear and tear. Check the tires, brakes, forks, mast, and hydraulic system for any damage or leaks. Check the engine and transmission for any unusual noises or vibrations. You should also check the forklift's service history to see if it has been well-maintained. 3. Consider the forklift's age and usage The age and usage of a forklift can affect its performance and reliability. A forklift that has been used heavily may have more wear and tear than one that has been used sparingly. Similarly, an older forklift may have outdated technology and may not be as efficient as a newer model. It's important to consider these factors when you're buying a used forklift. 4. Look for a reputable dealer When you're buying a used forklift, it's important to work with a reputable dealer that specializes in forklift sales and service. A reputable dealer will be able to provide you with a detailed inspection report and service history for the forklift. They can also offer you warranties and maintenance plans to protect your investment. 5. Test drive the forklift Before you make a purchase, it's essential to test drive the forklift to ensure it meets your needs and operates smoothly. During the test drive, you should check the forklift's steering, brakes, acceleration, and lifting capacity. You should also test it in different conditions, such as on inclines or over rough terrain. In conclusion, buying a used forklift can be a cost-effective solution for businesses that need heavy equipment for their operations. By following these tips, you can find a used forklift that meets your needs and provides reliable performance for years to come. Call or text Sean Cambern at (510) 470-9771 , or send email to sean@aaaforkliftplus.com for assistance with buying used forklifts, pallet jacks, reach trucks, order pickers, scissor lifts, walkie stackers, or other material handling equipment.

When it comes to running a successful warehouse or manufacturing facility, there are many factors that contribute to the bottom line. From overhead costs to labor expenses, it can be difficult to keep everything in check. But one factor that is often overlooked is warehouse forklift maintenance. Many business owners and managers assume that forklift maintenance is simply a necessary expense that comes with the territory. However, the truth is that regular maintenance can have a significant impact on your bottom line in ways that may surprise you. First and foremost, warehouse forklift maintenance can extend the life of your equipment. This means that you won't have to replace your forklifts as frequently, which can save you thousands of dollars in the long run. When forklifts are not properly maintained, they are more likely to break down or malfunction, which can result in costly repairs or replacements. In addition to saving money on equipment replacement, warehouse forklift maintenance can also have a positive impact on your productivity. When your forklifts are running smoothly, your employees can move products and materials more quickly and efficiently. This means that you can get more done in less time, which can help to boost your overall output and revenue. Another benefit of forklift maintenance is that it can improve safety in the workplace. When warehouse forklifts are not properly maintained, they can become a hazard to your employees and your facility. Regular maintenance can help to identify and address potential safety issues before they become a problem. This can help to reduce the risk of accidents and injuries, which can save you money on workers' compensation claims and lost productivity. Finally, warehouse forklift maintenance can help to improve the overall quality of your products and materials. When your forklifts are in good condition, they can handle delicate or fragile items with care, reducing the risk of damage or breakage. This can help to ensure that your products are of the highest quality, which can improve customer satisfaction and lead to repeat business. In conclusion, forklift maintenance is not just a necessary expense, but a valuable investment in your business. By extending the life of your equipment, improving productivity, enhancing safety, and ensuring quality, regular maintenance can have a significant impact on your bottom line. So if you are not on a preventative maintenance program then call or text Sean at (510) 470-9776 or send a message to sean@aaaforkliftplus.com and get started today!

Rent a new forklift for a week or a month, and if you decide to buy it before the end of the rental period, we will apply the rental fee towards the purchase price! We currently have new 5k LPG and electric forklifts in stock and ready for you to try. This program applies to our pre-owned equipment too. Contact Sean Cambern ( sean@aaaforkliftplus.com or (510) 470-9771 ) to make an appointment to try a new forklift toda y.

Propane forklift pros: Good for extreme temperatures or rough surfaces Consistent power throughout the shift Continuous operation: when the tank empties, simply replace with a full one Fuel can be available in remote locations Low upfront cost Propane forklift cons: Non-renewable fossil fuel Can’t be used for certain applications Price fluctuations and fuel availability Higher long term operating costs Noisier than electric forklifts Reduced field of vision and less maneuverable Safety and spill risks Operator training Electric forklift pros: Cleaner, no emissions and quiet Safe for food and medical applications Good for narrow aisle applications Lower cost of ownership Fewer moving parts Require less maintenance Electric forklift cons: Higher upfront cost Most electric forklifts aren’t designed for outdoor use Battery charging time requirements Must be charged in a specific location Call Sean at (510) 470-9771 to learn more about propane and electric-powered forklifts.